So after spending time at the Bigfish workshop/mancave I realized I needed to do some simple but effective upgrades and maintenance to my lathe and dupe.

In no particular order here's what I spent a day doing

Wrapped the prof m blade holder in electrical tape, so that it didn't wiggle, and the set screw has something to hold onto.

Flipped the blade around, I probably cut 200/300 plugs with the first side

Upped the speed on the delta lathe to highest setting

Tightened all motor mounts.

Tightened chain on Vega

Tightened carriage on vega. Which is a pain cause there's 4 set screws and a little turn makes a big deal.

Tightened red arm on vega, removed any play

Moved the lathe over 18" on the work bench, put a thin rubber pads under the feet before bolting it back down, to help with the vibration

Cleaned all tracks on the vega and rewaxed the deck on it and the lathe.

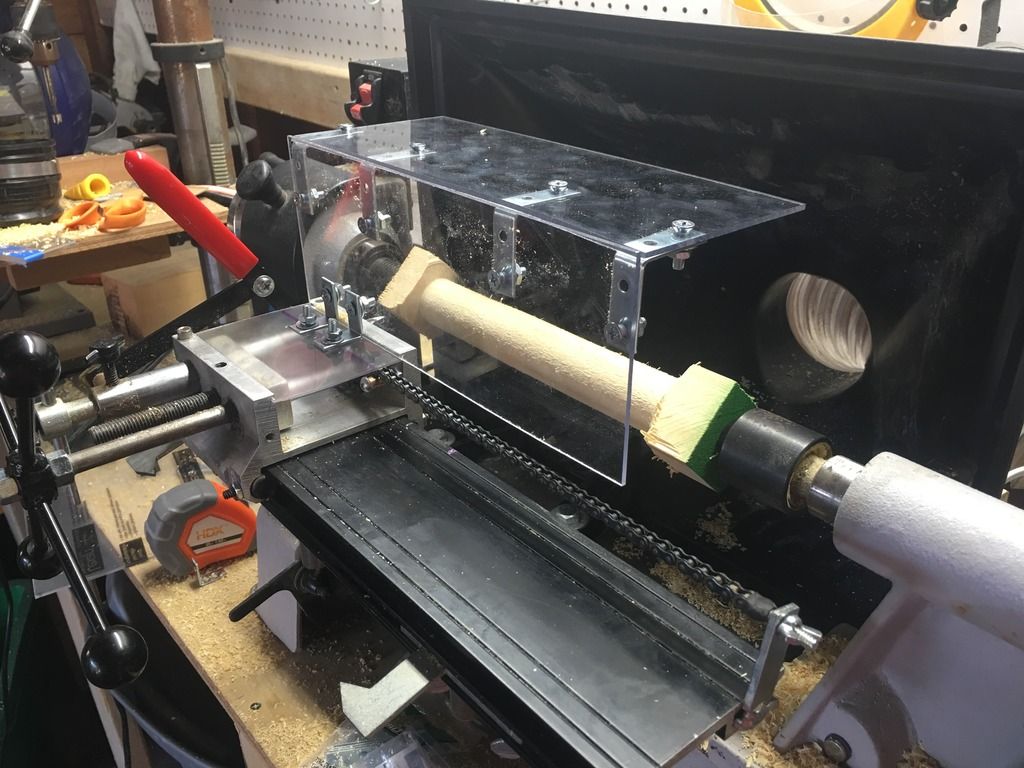

Made a plexi motor cover that's angled into the dust collector hood

Upgraded the dust collector, still working on a system that will help catch the chips and dust. More concerned about the chips flying everywhere

Worked in making a deflector shield that mounts to the vega and will knock the chips down onto the plexi plate above the motor and into the dust collector

Found out I need to close the ends off as much as possible to stop the chips from shooting to the left and right. Which is what I'll work in this week. Better than it was before without it but can be better

Found some clear plexi/lexan storage bins that I think will work great once I get the overall design done. Hoping to find something close and just cut away the excess and mount it.

It's getting there.