| |

|

|

|

|

|

|

|

| |

| Plug Building - Got Wood? Got Plug? |

|

12-05-2006, 11:21 AM

12-05-2006, 11:21 AM

|

#1

|

|

Registered User

Join Date: Mar 2005

Location: Attleboro, MA

Posts: 453

|

Homemade duplicator

Here's my take with a lot of help from ProfessorM...  .(THANKS I owe you a beer...or two).

Took a couple weeks to pick away at it but I finally finished up this week. Still have some patterns to make yet. It's tough to see but I used Lexan to make my patterns from. Easy to machine and shape, plus, I have a lot on hand. I was actually able to use it on the first shot with no tweaking.......cuts like butter but will experiment with different cutters. It takes a little bit of "touch" but I am happy with the results. I'm not sure I'll ever touch a roughing gouge again.

|

|

|

|

|

12-05-2006, 11:22 AM

12-05-2006, 11:22 AM

|

#2

|

|

Registered User

Join Date: Mar 2005

Location: Attleboro, MA

Posts: 453

|

|

|

|

|

|

12-05-2006, 01:57 PM

12-05-2006, 01:57 PM

|

#3

|

|

Great White Scup Hunter

Join Date: Nov 2006

Location: In the Corner...

Posts: 2,251

|

Very nice.........

|

|

|

|

|

12-05-2006, 02:06 PM

12-05-2006, 02:06 PM

|

#4

|

|

Registered User

Join Date: Oct 2006

Location: Riverside,Rhode Island

Posts: 50

|

Nice mugz  |

|

|

|

|

12-05-2006, 03:39 PM

12-05-2006, 03:39 PM

|

#5

|

|

Registered User

Join Date: Nov 2005

Location: Southern Maine

Posts: 178

|

Wow....That's pretty slick!

|

|

|

|

|

12-05-2006, 03:59 PM

12-05-2006, 03:59 PM

|

#6

|

|

Certified Mass-hole

Join Date: Jun 2003

Location: Jackson, NJ but born and raised in Massachusetts.

Posts: 1,223

|

The dup lookd good. Try to get some clearance in that tool to help prevent some of the chatter and rough surfaces. It will mean alot less sanding.

|

|

|

|

|

12-05-2006, 04:05 PM

12-05-2006, 04:05 PM

|

#7

|

|

Registered User

Join Date: Mar 2005

Location: Attleboro, MA

Posts: 453

|

Quote:

Originally Posted by Charleston

The dup lookd good. Try to get some clearance in that tool to help prevent some of the chatter and rough surfaces. It will mean alot less sanding.

|

Clearance? Please Explain |

|

|

|

|

12-05-2006, 05:15 PM

12-05-2006, 05:15 PM

|

#8

|

|

Uncle Remus

Join Date: Mar 2003

Location: Lakeville Ma.

Posts: 14,773

|

Looks great. I think he means what we discussed about the insert I told you about. It has a for lack of a word I can't think of right now a cupped cutting surface on top, very sharp edge designed for cutting soft material like aluminum. The flat top surface cutter you are using basicly forces the wood off the plug and causes tearing of the wood. The sharper edged insert actually cuts the wood, thus smoother results. I hope that is understandable.  P. |

"A beach is a place where a man can feel he's the only soul in the world that's real"

|

|

|

12-05-2006, 07:22 PM

12-05-2006, 07:22 PM

|

#9

|

|

Registered User

Join Date: Mar 2005

Location: Attleboro, MA

Posts: 453

|

Gotcha......I see what you mean now. I will look for one. Know the technical name?

|

|

|

|

|

12-05-2006, 10:32 PM

12-05-2006, 10:32 PM

|

#10

|

|

Certified Mass-hole

Join Date: Jun 2003

Location: Jackson, NJ but born and raised in Massachusetts.

Posts: 1,223

|

Take a look at some of the carbide inserts that are made for insertable tooling. Find one with a nice cupped center that blends up to mnice sharp sides (allowing the wood to be cut clean). Make a square holder the same dims as the tool in the dup now. You'll be all set.

|

|

|

|

|

12-05-2006, 10:46 PM

12-05-2006, 10:46 PM

|

#11

|

|

Registered User

Join Date: Dec 2004

Location: North Fork

Posts: 2,260

|

Quote:

Originally Posted by Mugz

Gotcha......I see what you mean now. I will look for one. Know the technical name?

|

Indexable carbide insert with a chipbreaker. |

|

|

|

|

12-06-2006, 09:15 AM

12-06-2006, 09:15 AM

|

#12

|

|

Registered User

Join Date: Mar 2005

Location: Attleboro, MA

Posts: 453

|

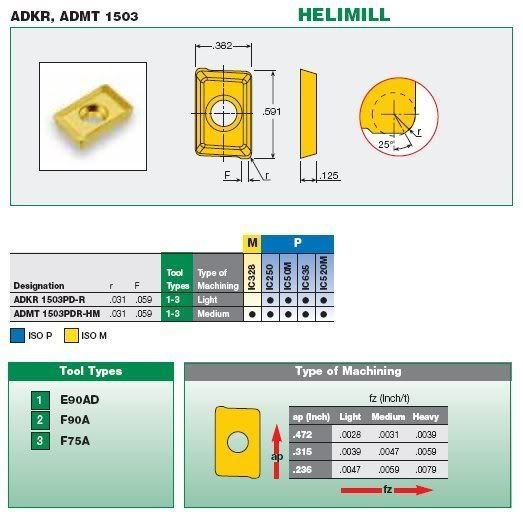

Like this? I couldn't find a triangle shaped bit that was cupped. I can find some triangle cutters that have 11 or 15 degree clearance though but not cupped.

|

|

|

|

|

12-06-2006, 09:18 AM

12-06-2006, 09:18 AM

|

#13

|

|

Certified Mass-hole

Join Date: Jun 2003

Location: Jackson, NJ but born and raised in Massachusetts.

Posts: 1,223

|

Quote:

Originally Posted by Mugz

Like this? I couldn't find a triangle shaped bit that was cupped. I can find some triangle cutters that have 11 or 15 degree clearance though but not cupped.

|

These inserts are for Milling operations. Look for Turning operations

They are exactly what you need.......or simply ask eastendlu  He knows all about that stuff! |

|

|

|

|

12-06-2006, 09:26 AM

12-06-2006, 09:26 AM

|

#14

|

|

Registered User

Join Date: Mar 2005

Location: Attleboro, MA

Posts: 453

|

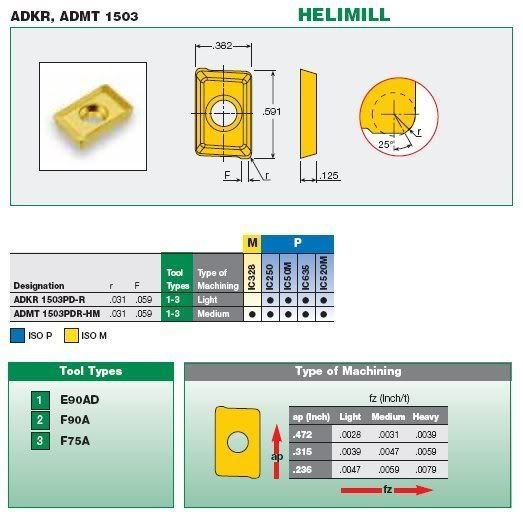

I have these........with a chip breaker. Not sure if they are negative or positive chipbreakers......

|

|

|

|

|

12-06-2006, 09:53 AM

12-06-2006, 09:53 AM

|

#15

|

|

Certified Mass-hole

Join Date: Jun 2003

Location: Jackson, NJ but born and raised in Massachusetts.

Posts: 1,223

|

Quote:

Originally Posted by Mugz

I have these........with a chip breaker. Not sure if they are negative or positive chipbreakers......

|

That looks promising. Try to find one with a sharper angle so you can turn closer to the end of the blank. Looking good  |

|

|

|

|

12-06-2006, 11:32 AM

12-06-2006, 11:32 AM

|

#16

|

|

Uncle Remus

Join Date: Mar 2003

Location: Lakeville Ma.

Posts: 14,773

|

Yes chip breaker, lu is right . I told you I have exactly what you need but it will cost you as I need to buy them. The one above is not for aluminum. You need something that is made for aluminum or plastic not hard materials like stainless, etc. and a 30 degree angle at the tip so you can get into small dia. next to larger dia.'s. You also need the correct hold down screw too if you are going to make your own holder. P.

|

"A beach is a place where a man can feel he's the only soul in the world that's real"

|

|

|

12-06-2006, 09:44 PM

12-06-2006, 09:44 PM

|

#17

|

|

Registered User

Join Date: Oct 2002

Location: Kentucky

Posts: 1,442

|

I'm always impressed by the metal work some of you guys do. I'm lucky if I can mill out a weight slug cavity in a blank mold!

Jigman |

|

|

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -5. The time now is 08:51 AM.

|

| |